How Welding Inspection Madison Makes Sure High Quality and Security in Fabrication

Wiki Article

Exactly How Effective Welding Assessment Improves Structural Integrity and Durability

In the realm of construction and design, the significance of welding inspection can not be overstated, as it plays a pivotal duty in ensuring structural stability and prolonging the lifespan of jobs. By deploying a variety of sophisticated evaluation strategies, such as ultrasonic and radiographic testing, experts can determine defects that could endanger the dependability of a structure. The question continues to be: exactly how do these precise procedures convert right into substantial advantages for resilience and security? Join the exploration of exactly how efficient welding assessments can change possible vulnerabilities right into strengths, contributing to the enduring success of constructions.Importance of Welding Assessment

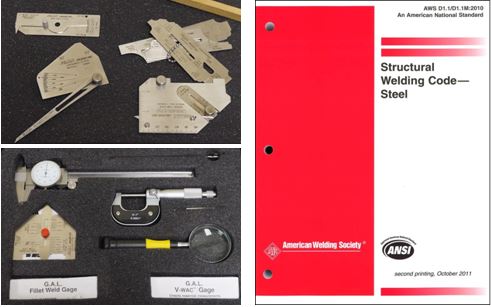

Making certain the structural stability and security of welded constructions requireds extensive welding examination processes. Welding evaluation serves as an important protect in the construction and production sectors, where the toughness and durability of joints substantially impact the overall performance of frameworks.Along with security, welding assessment plays a vital function in quality control. By adhering to established requirements, evaluations ascertain the consistency of welds, making certain that each satisfies the desired strength and visual requirements. This uniformity is necessary not just for security but additionally for preserving the track record and reliability of fabricators and suppliers. Governing conformity is a substantial chauffeur of welding evaluation practices. Sector requirements and codes, such as those from the American Welding Culture (AWS) or the International Company for Standardization (ISO), necessitate adherence to strict standards, underscoring the importance of assessments in meeting these legal and specialist responsibilities.

Trick Evaluation Techniques

Ultrasonic Examining (UT) utilizes high-frequency acoustic waves to spot subsurface flaws, using accurate details concerning weld integrity without triggering any damages. Radiographic Evaluating (RT), including X-rays or gamma rays, provides a thorough picture of the weld's interior structure, revealing hidden imperfections. Magnetic Fragment Testing (MPT) is one more non-destructive technique, especially efficient for finding surface area and near-surface suspensions in ferromagnetic materials.

Penetrant Testing (PT) entails the application of a fluid color to reveal surface-breaking flaws, providing a uncomplicated and affordable option for non-porous materials. Each strategy has its certain applications, toughness, and limitations, and often a combination of methods is employed to achieve comprehensive inspection outcomes. Proficiency of these techniques improves the reliability and sturdiness of bonded frameworks, lining up with safety and efficiency assumptions.

Identifying Common Issues

Porosity, identified by gas pockets within the weld, minimizes the weld's strength and sturdiness. It commonly arises from pollutants or incorrect protecting gas. Fractures, which can take place during or after welding, pose considerable dangers because of their potential to pop over here circulate under tension. They commonly arise from excessive anxiety, quick cooling, or incorrect weld layout.

Insufficient blend, where the weld steel stops working to bond totally with the base material, weakens the architectural stability, causing weak joints. This defect typically originates from insufficient warmth input or inappropriate welding strategy. Slag additions occur when non-metallic materials are trapped in the weld, compromising its toughness and quality. These are commonly an outcome of insufficient cleansing in between weld passes or improper flux use.

Determining these defects through meticulous evaluation approaches, such as visual examination, ultrasonic screening, or radiography, is essential. Attending to these problems guarantees weld top quality, ultimately supporting the structural honesty and safety and security of the developed atmosphere.

Enhancing Structural Efficiency

Recognizing the importance of identifying usual weld defects normally leads to discovering techniques for boosting architectural performance. The foundational method for boosting efficiency requires employing sophisticated welding strategies and materials that reduce flaw occurrence. Using high-grade filler products and making sure proper warm control can substantially minimize problems such as porosity and cracking, therefore enhancing the weld's integrity.Integrating advanced welding innovations, such as laser welding and rubbing stir welding, further enhances architectural durability. These techniques offer exceptional precision and minimized thermal distortion, straight affecting the resilience and stamina of the bonded frameworks. Adopting automated welding systems can guarantee constant and repeatable weld high quality, reducing human mistake.

Additionally, implementing strenuous pre-weld and post-weld procedures is important. Appropriate joint layout, surface area prep work, and stress-relieving procedures add to optimal weld performance. Conducting comprehensive pre-weld assessments permits early detection of prospective problems, helping with timely corrections prior to they endanger the framework.

Long-lasting Advantages of Inspection

Through cautious evaluation methods, the lasting benefits to structural honesty ended up being increasingly noticeable. Detailed and regular welding examinations play a vital role in protecting against structural failings by determining defects and incongruities early in the building procedure. This find out positive strategy guarantees that possible issues are resolved before they can jeopardize the safety and security and toughness of structures. By capturing defects early, expensive fixings and downtime are reduced, eventually extending the life expectancy of the framework.

In addition, regular evaluations contribute to maintaining conformity with market criteria and regulations, consequently avoiding economic and legal repercussions. This adherence to high quality assurance not only boosts the integrity of the framework yet additionally cultivates count on among stakeholders, consisting of clients, engineers, and regulatory bodies. The extensive paperwork of assessment results works as an important resource for future repair and maintenance efforts, assisting in notified decision-making.

In addition, effective assessment methods support technology by including sophisticated modern technologies such as non-destructive screening and electronic imaging, which can enhance accuracy and performance. This technical assimilation further emphasizes the commitment to excellence in architectural stability. Ultimately, purchasing meticulous welding examinations is a sensible strategy that generates significant lasting benefits, protecting both the monetary and physical investment in framework tasks.

Final Thought

Effective welding examination plays a crucial duty in boosting structural honesty and durability by recognizing flaws early in the construction procedure. Using strategies such as visual examination, ultrasonic testing, and radiographic screening makes certain the discovery of issues like cracks and porosity that endanger weld strength. Strenuous evaluations make sure compliance with market requirements, thereby prolonging the life expectancy of frameworks, reducing pricey repair work, and promoting stakeholder trust fund in the dependability and security of welded building and constructions.

In the realm of building and construction and design, the significance of welding assessment can not be overemphasized, as it plays an essential role in making certain structural stability and expanding the lifespan of jobs.Making sure the architectural honesty and safety and security of welded buildings mandates extensive welding assessment procedures.Building upon the importance of welding assessment in securing architectural honesty, recognizing the key evaluation techniques ends up being vital for efficient application. Effective welding evaluation incorporates an array of techniques created to examine weld top quality, making sure conformity with rigid engineering requirements - Welding Inspection Madison.Effective welding examination plays a crucial role in Web Site improving architectural stability and durability by recognizing flaws early in the building process

Report this wiki page